This is a review of my 88mm deep carbon race wheelset from 3SIXTY5 Cycling. These wheels have been nothing but bombproof and after putting 1800km on them I figured its time to write down my thoughts on them.

I have had the pleasure of being part of the 3SIXTY5 Cycling Ambassador Team for 2015. With this came the responsibility of raising awareness of not only a great company (3SIXTY5 CYLING) but a promise to be a positive representative for the brand whenever possible. Showcasing a set of wheels that I believe to be some of the fastest in the business and strong enough train on was something that I felt would be a fun task.

Keep in mind that this is my opinion and I was not asked to write this review but I felt the products and company deserve it.

Every chance I got to introduced people to the brand and direct questions or customers towards Chris Day and the guys from 3Sixty5 was a blast. Chris is a outgoing and fantastic family man who has a knack for business and A++ customer service. It was evident that the 3SIXTY5 Cycling brand was growing quickly because every race I attended this summer brought with it more and more of their wheels on bikes. People constantly ask me where my equipment is from or if I can suggest anything for them and it was a pleasure to introduce people to this company that had showed me such good will and support. Along with some of my own fantastic results while riding these wheels came some great opportunities to meet other people that were either ambassadors for the brand or just happy customers. People always have wonderful things to say about 3SIXTY5 Cycling wheels and their buying experience which was always great to hear. Passing along feedback to Chris I could always tell how thankful he was to hear even through email.

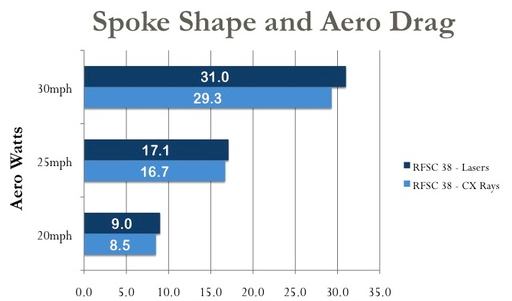

I purchased my wheels in May of 2015 after much deliberation and some consultation with Pro Triathlete Cody Beals, decided on the exact same wheel set he would be running for his 2015 race season the FAT88 Carbon Clinchers. Cody and I talked about spokes, hubs, sizes and more and what we both agreed on was fatter was better! Aero spokes were also added to keep the air flow as stable as possible over the wide rims. When deciding on hubs it was a easy decision because like everything there was a budget and the spoke upgrade out weighed the hub upgrade. After doing some online research decided that easy bearing replacement and maintenance of the Novatec Hubs they would work fine but aero spokes were a must.

FAT88 CARBON CLINCHER WHEELSET

Model: FAT 88mm Carbon Clinchers

Width: 25mm

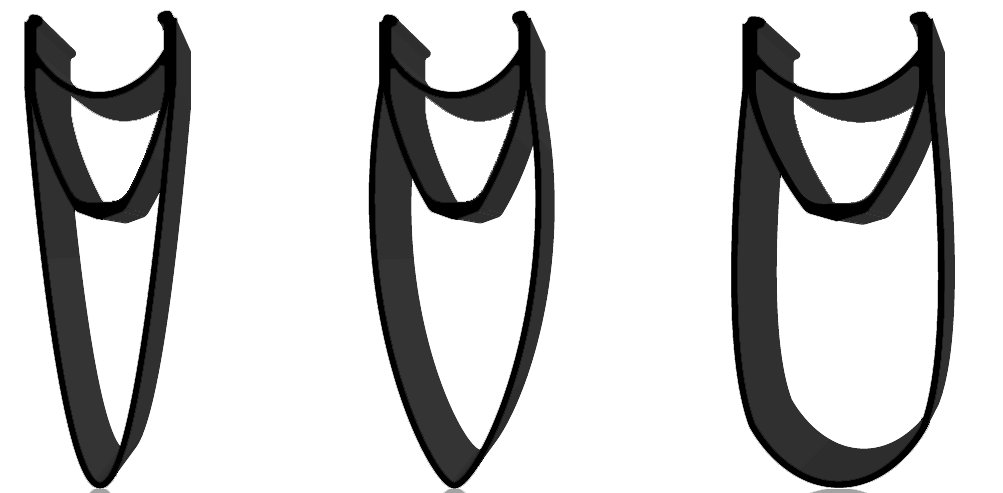

Shape: Toroidal “U”

Finish: 3K Glossy

Spokes: Sapim CX-Ray (F20/R24, black)

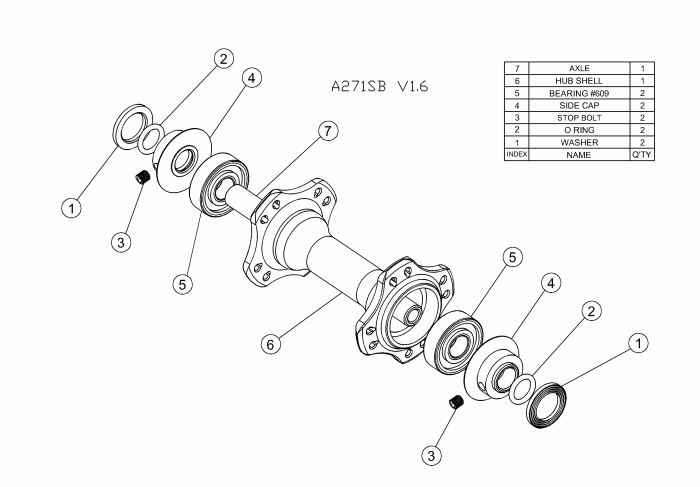

Front Hub: Novate A271SB (red)

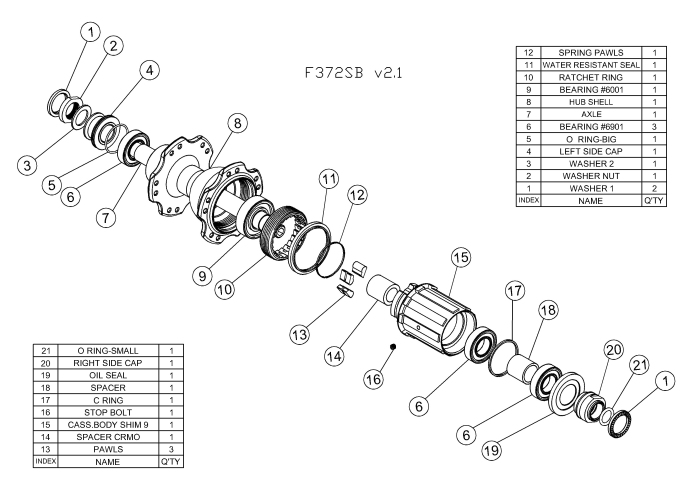

Rear Hub: Novate F372SB (10 speed, red)

Tires: 25mm Continental 4000S II

I placed my order online and within a few weeks received the notification from Chris that my wheels were ready to be shipped. All their wheels are hand built by Winston, another great guy who has years of experience in the cycling industry and takes the time to make sure every wheel is built to his high standards. I took the opportunity to drive to 3SIXTY5 Cycling since it is only a hour or so from home to pick them up in person. I had a race in a few days and didn’t want anything to happen during shipping (OCD…..). I got in my car and flew down to Cambridge excited for these new wheels and to meet Chris. Upon arriving Chris greeted me with a smile and was just as excited as I was about me and the new wheels. I had brought my bike along with tires/tubes, cassette and tools ready to install in his driveway, which I did. We both got a kick out of it but it my opinion why not. At the time my only concern was that my bike frame might be a little finicky because it was never meant to run wheels that were 25mm wide. Tires mounted (no leavers necessary) and tubes full of air I road up and down Chris’s street with a large smile on my face.

As I road up and down the street right away a few things were clear :

- The wheels fit my bike frame but it was close!

- I needed to get carbon brake pads (forgot them at home)

- Brakes would tuning to accommodate the much larger wheels.

- With lower tire pressure these were so comfortable to ride on.

- Weight was not bad and they spun up quickly.

- Hub bearings were smooth and quiet.

- Wheels were true and straight.

- Carbon wheels make gnarly sounds (whoosh whoosh whoosh)

After packing everything back up in the car Chris and I talked shop and got to know one another a little better before it was time to go back home. I don’t think I stopped smiling the whole drive home like a kid who just got a birthday present at the age of 3.

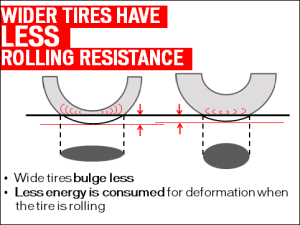

Rim Width (25mm), Depth (88mm) & Toroidal Shape

2015 was host to some great racing and results for me and credit is due to the fantastic wheelset there is no question. Some of my fastest bike splits for both racing and time trials ever came while riding on these wheels! The wheels were rock solid and I used them for training and racing alike not once worrying that they might get damaged or have a issue while out on a 80k training ride. The width being 25mm these wheels are indeed wide and with all the latest research saying wider is faster and lower tire pressure is faster the research I did pointed my to the latest wheels 3SIXTY5 had. I am a fan of clincher tires but not opposed to tubular. Clincher wheels are always heavier that tubular just due to design, there is more material in them. Now there are plenty of pros and cons to both tubular and clincher so I am not even going to start to say one is better than the other that is for you to decide as an individual rider.

I did have to modify my rear brake to allow the pads to slip lower down to accommodate the brake pads, this was only specific to my bike because it is a 2010 model and was never designed for wheels over 23mm. Despite this I was able to get them to work with the 25mm tire also very wide for my TT bike frame. The tolerances are very close but I have never had the tires rub on my frame, if you have an Argon E112 or similar bike I can confirm the FAT88’s fit!

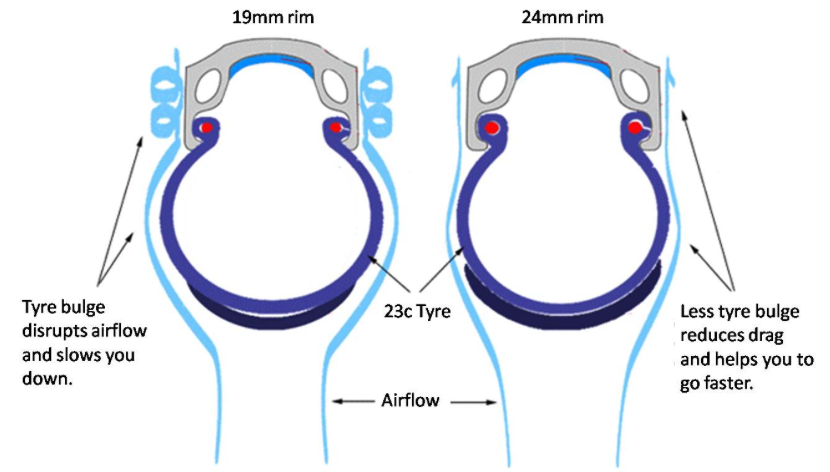

Wider rims allow for better air flow from the over tire, this results in better aerodynamics and less turbulent air.

With wider wheel profiles also comes a new shape in look and design. This this new development in shape allows for better air flow over the surface of the wheel and at higher yaw angles this means more speed. The FAT88’s are not only wide they are a very tall rim at 88mm and have this toroidal shape making them the fastest style wheels out there. Wind tunnel testing has proven that the wider shape is not only faster but it is also easier to handle in higher cross winds. To do a my own test I road my SRAM S60’s (60mm deep) on a windy day for 10k and then switched to the FAT88’s and did the same. The 88’s are considerably taller than the SRAMS but what I found was surprising. My front wheel felt planted more than before despite the gusty conditions I was able to maintain control better. When I was hit with a gust the wheel was almost sucked to the ground and was far less violent like the 60’s. Now I realize that a wider tire helps with stability but that does not out weight the difference in height of the 88’s! The “U” shape allows you to ride with more confidence in windier conditions that is for sure. I also noticed that with the wind at a high degree of yaw or blowing slightly off the back I could feel the wind pushing these wheels forward. It is a feeling like no other when you are being assisted by the wind and I road the 10k a few km/hr faster on the 88’s due to the “push” that they developed, it was like riding with sails attached to my bike.

Example of a older wheel shape (19mm), early toroidal and a modern “U”shape toroidal rim profile (24+mm).

Example of a older wheel shape (19mm), early toroidal and a modern “U”shape toroidal rim profile (24+mm).

Tires & Pressure

I ride at lower than most (85 PSI) because I only weight 64-66kg. Tire pressure is something that has endless research behind it and after conducting my own “scientific” research I decided that 85 worked best for me. I road up and down a section of road and chose what felt best! Lower pressure has a few other benefits like improved ride quality which I noticed on these wheels. Roads that were bumpy before or uneven suddenly felt smooth like riding on a cloud. Anyone who has ridded a bike (especially a TT bike) knows that there is nothing worse than being in “aero” position going down a bumpy road and having your forearms smashed repeatedly of the bars. I backed up these initial results after riding some time trials this summer and what I found was slightly faster results on 85PSI as apposed to 90PSI, but much more comfort at the lower which may entail have helped me ride faster. The tire I choose to compliment the wheels are Continental 4000S II 25mm wide. Wider tires have lower rolling resistance.

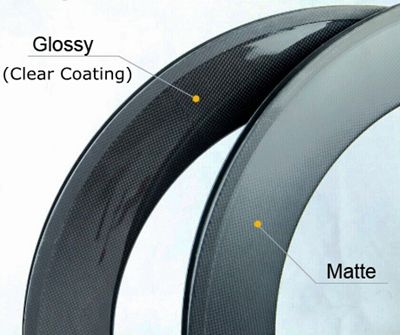

Wheel Finnish

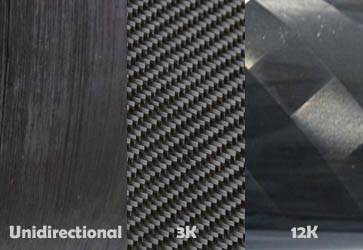

Choosing the 3K glossy finish was simple because my bike already has a glossy finish. The forks on my Argon have a 12K weave but 3K was my only option and it matched the closest. If you are wondering what the differences are between 3K, 12K and UD below is image to showcase them. Keep in mind that no matter the finish and weave structurally it is the same and is purely cosmetic as is the gloss vs matte finish cosmetic. The finish is great on my wheels and has stood up to rain, mud and even gravel roads…….(construction zone).

3K

“Woven fabric is the most common and versatile way to work with carbon fiber. Typically bunches of carbon fiber strands (yarn) are woven bi-directionally (the weft and the warp). The manner in which the weft and the warp are interwoven is the weave pattern. But why woven fabric presents different appearance? The difference is carbon used. We all know that the smaller the ‘K’, the thinner carbon yarn is, the greater of ‘K’, the thicker carbon yarn is. This is consistent with what you can see: 1k looks dense and thin (1k carbon yarn is thinner), 3k is thicker, and 12k looks the thickest with sparse weave (12k carbon yarn is thicker). The advantages of woven fabric are that they are good-looking (often used for exterior materials), and high inter-layer shear stress, a disadvantage is that it’s expensive (additional woven costs), so considering the intensity and costs, bicycle factories also prefer to small amount of woven fabric on outer appearance.”

UD

“Unidirectional carbon fabric is a reinforcement where all (or almost all) of the carbon fibers are aligned in the same direction. The only thing holding the fibers together will be occasional strands of either carbon or polyester running across the fibers at 90 degrees. Most of us know unidirectional material is used in applications where all of the forces on a part will be in one direction (such as the body of an archery bow). Alternate layers of unidirectional fibers can be positioned with different orientation to allow any combination of bias for the strength of the part to be achieved.”

Spokes

Sapim CX-RAY spokes have been around a long time and have a proven track record or quality,strength and aerodynamics. The FAT88’s are strong wheels and with the pairing of Sapim spokes ensured that they would roll true for years. I have not had to true a wheel yet thanks to the hand assembly and proper tensioning from Winston these light and durable spokes have preformed great.

“The CX-Ray still receives the best results in fatigue testing of any spoke. Its unique strength and flexibility make the CX-Ray suitable for most bicycle disciplines. The middle section of the spoke is drawn then pressed in a special mold to form its specific profile. CX-Ray spokes are used by top bike racers and triathletes around the world. Even downhillers use them, recognizing their strength and flexibility. Special alloy treatment and sophisticated production make this all possible.”

1 Watt = 3 seconds in a 40K TT at 30mph

1 Watt = 3 seconds in a 40K TT at 30mph

Hubs

Front – Novatec A271SB

The Novatec hubs like is said above are easily serviceable and have a decent track record. I have only had one issue with the rear hub and I will touch on that in a bit. The front hub a Novatec A171SB weighs 107g, 20 spoke holes, 2 sealed bearings and comes in red, black or white. It is a simple and string design, two bearings on either side of the hub and an axle. This means buttery smooth spinning and when maintenance need to be done you just remove the bearings and put in new ones. My front hub spins forever with my bike in the work stand i can spin the front wheel and it goes round and round for many minutes before is starts to slow down. I did a test between my front wheel and a ZIPP 404 (3 year old) and the Novatec hub spun for a lot longer to my surprise.

Rear – Novatec F372SB

The rear hub weighs in at 277g has 24 spoke holes, 4 bearings and comes in the three colours also. This hub is a basic 3 pawl hub, a pawl is the part of the cassette body that actually transfers the force from your cassette to the hub, making the wheel turn. Your cassette is mounted to the “cassette body” and then you stop peddling and coast you get the “buzzzzz” from these pawl teeth singing open and closed inside your rear hub.

Here is a video that explains it in some more detail.

The only issue I have had with the wheels in the 1800k was with the rear hub and that was a manufacturing problem with the hub body itself. After getting in touch with Chris he quickly RMA’d the rear wheel and Winston worked his magic once again installing a new rear hub for me within days. Customer service like I said earlier has been nothing short of fantastic and since it was a warranty issue Chris was right on it and even providing me a loaner wheel in the mean time. Service is second to none from these guys! After the initial hub problem I have not nay issues with and chalk it up to my bad luck….. it was like it never happened at all now. Easy serviceability again with the rear hub and bearing or axle replacement is easy as pie.

Conclusion

To wrap it all up I must say that these wheels have been fantastic, despite the one little hiccup that was beyond anyones control the FAT88’s have been one of my best purchases when it comes to bike upgrades. The wheels may not be as light as some but that is due to the heavier but cheaper hubs. Easily remedied down the road with an simple upgrade to a 3SIXTY5 260 road hub saving weight and with a better pawl system, I might just do this for next year. Fast is an understatement just ask Pro Triathlete Cody Beals who also set some blistering bike splits this season racing 70.3 Ironman’s. No matter how windy it is out there the toroidal shape helps keep these wide rims glued to the pavement, pair them with a Conti 4000SII or similar fast tire and these things are weapons on the race course. I train on these and race on these and the only time they come off my bike to when it goes on the CompuTrainer. Looking forward to what 2016/17 brings for this company because they are already expanding to a store front and business is good.

The wheels from 3SIXTY5 Cycling truly “Fast Enough to Win, Tough Enough to Ride Year Round” Click on their logo below and go checkout their site.

New storefront opening mid December – early January 2016. Follow along on their Facebook page here.

2 Comments

Pierre · March 28, 2016 at 8:55 am

Wow, that is one very comprehensive product review! Thanks for putting it together. I was wondering, have you had much experience using these wheels in wet conditions? If so, how did you find the brakes relative to other carbon rims and relative to aluminum braking surfaces? I just got a pair of Lunar 45’s which Chris is building up for me. Can’t wait to give them a go!

Spencer · March 30, 2016 at 4:57 pm

I have ridden in damp conditions but never wet, braking has always been fine. Make sure that you run carbon specific pads. I have a set of aluminum / carbon wheels and I’m partial to running salmon koolstop pads (super great braking wet or dry). My carbons are a lot louder and not as quick to stop but on my TT bike I don’t find it an issue.

Comments are closed.